By Andy Billingham, Managing Director – EMKA (UK) Ltd

A major part of the performance of a typical sealing profile comes from correctly understanding the structural factors which support and control the rubber profile of whatever specification chosen and which must be correctly determined in order to ensure a satisfactory installation in the long term. We shall cover here the more important aspects worthy of consideration in the design of complex steel inserted extruded rubber profiles, particularly in connection with applications such as:

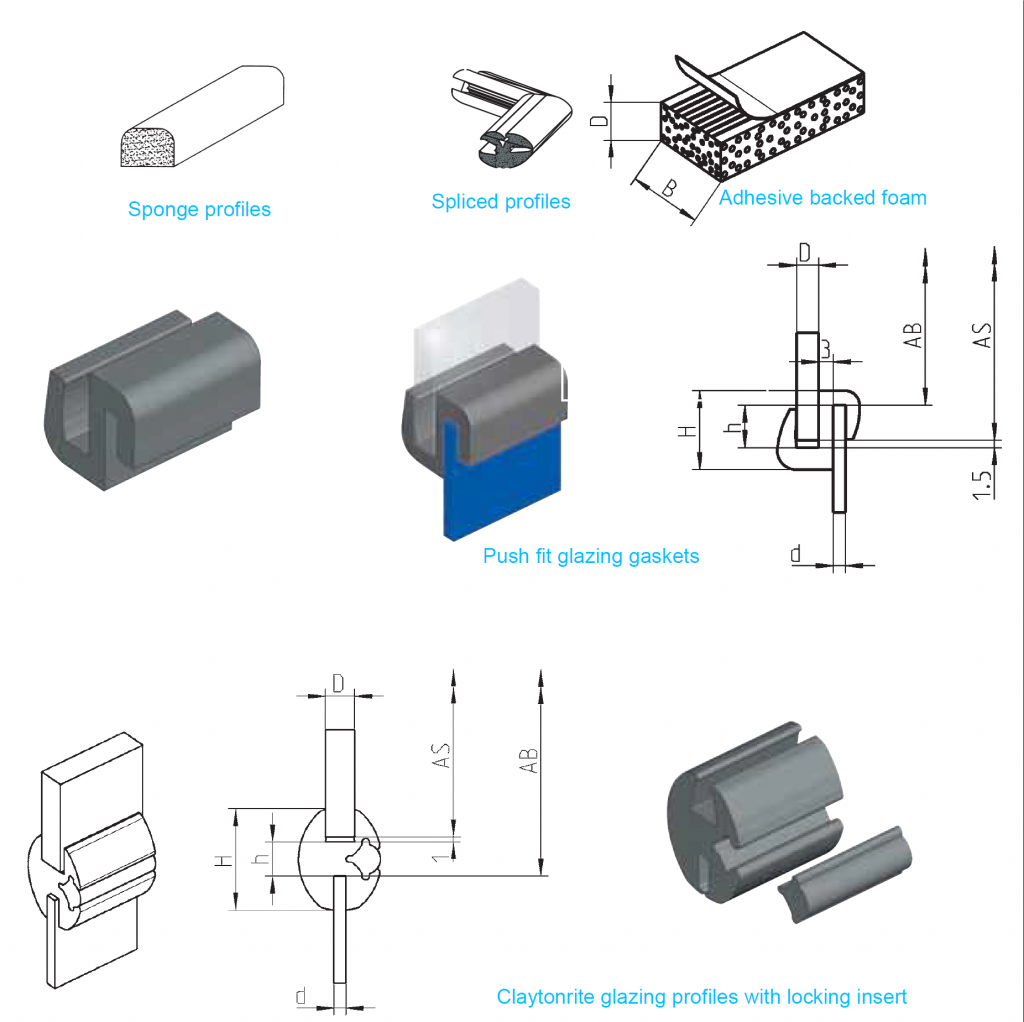

- Edge protection profiles, sealing profiles with and without metal carrier

- Sponge rubber profiles with and without bonding (Self/Acrylic Foam)

- Rubber glazing and filler profiles

- Dual Hardness rubber profiles

- Door sealing profiles

- Custom-made products, frames, rings, lengths, butyl, mastic, flock coating, notching, gluing, slip coating, etc.

Typical applications include electrical/electronic cabinets, automotive, windows/construction, oil and gas industry as well as general industrial generic products. These installations are predominately concerned with exclusion of air, dust, gas and/or water as either partial or complete seals to lids, doors or panels and will often include standard profiles – possibly in a custom solution. Your supplier should be in a position to advise on this and especially where a custom design is required then to guide – and the following is intended to inform that process.

At a fundamental level industry standard manufacturing tolerances are covered by the international standard DIN ISO 3302 with tolerances of custom length based upon DIN ISO 3302 -1.

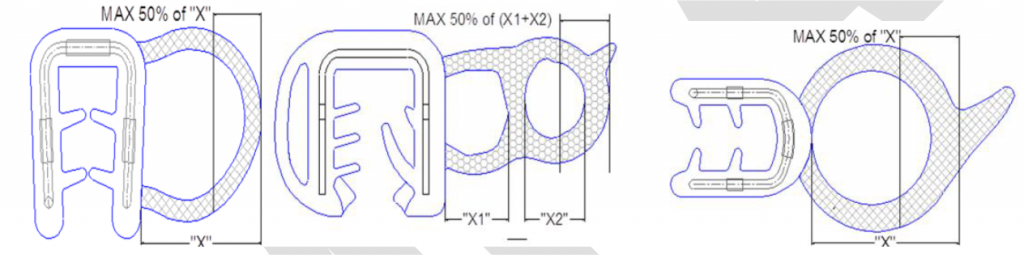

With this in mind the designer should determine the correct degree of compression (for bubble sealing profiles). The compression of a typical sealing edge protection profile should be a maximum of 50% as otherwise the compression and recovery can be adversely affected. It is recommended the profile should be compressed 30-40%. Should the profile have two cavities then the value should be applied to each cavity.

For sponge rubber profiles the comparable parameter is the compression set since an essential for the application of a sealing strip is the enduring deformation. The most common characteristic is the compression set (DVR) ASTM D395. To determine this value, a cylindrical test body is compressed by-25% and then stored for a pre-set time at a specific temperature. Thirty minutes after release, the height is measured at room temperature again, and from the result, the enduring deformation is identified.

A DVR of 0 would mean that the test body has reached its original height again (unlikely in reality), a DVR of 100% shows that the test body has no recovery and would remain completely deformed. Why is the compression set such an important parameter?

When a flange gasket is compressed to a specified thickness (for example in a door seal) it exerts a pressure on the surface of the flange but after a while this pressure will reduce because the rubber deforms and takes a set. If the DVR is too high, the elastic performance and the sealing effect will decrease and the seal may cease to function properly.

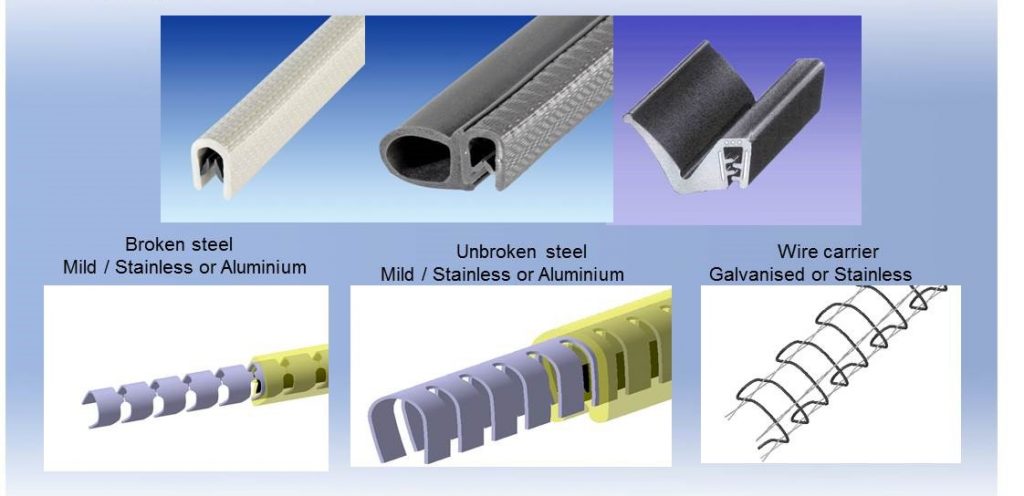

Underlying the rubber seal itself is often a steel strip or wire carrier, usually chosen to support the rubber mechanically and to provide a means of installation. By using either steel or wire carrier, the edge protection sections will grip well, without the use of adhesives or tapes – however, the use of a steel carrier will also have a higher clamping effect than a wire carrier and is therefore advised where there are high-vibration applications.

The disadvantage of a profile with an unbroken steel carrier strip is seen in a restricted bending radius. This can be solved by breaking the connecting sprags. However, an uneven surface may develop if this is done. In most technical applications the aesthetics will usually be considered irrelevant.

Consequently, the choice of either a steel or wire carrier largely depends on the application situation, and the desired appearance. (Where aesthetics are important, the “hungry horse” effect can be disguised).

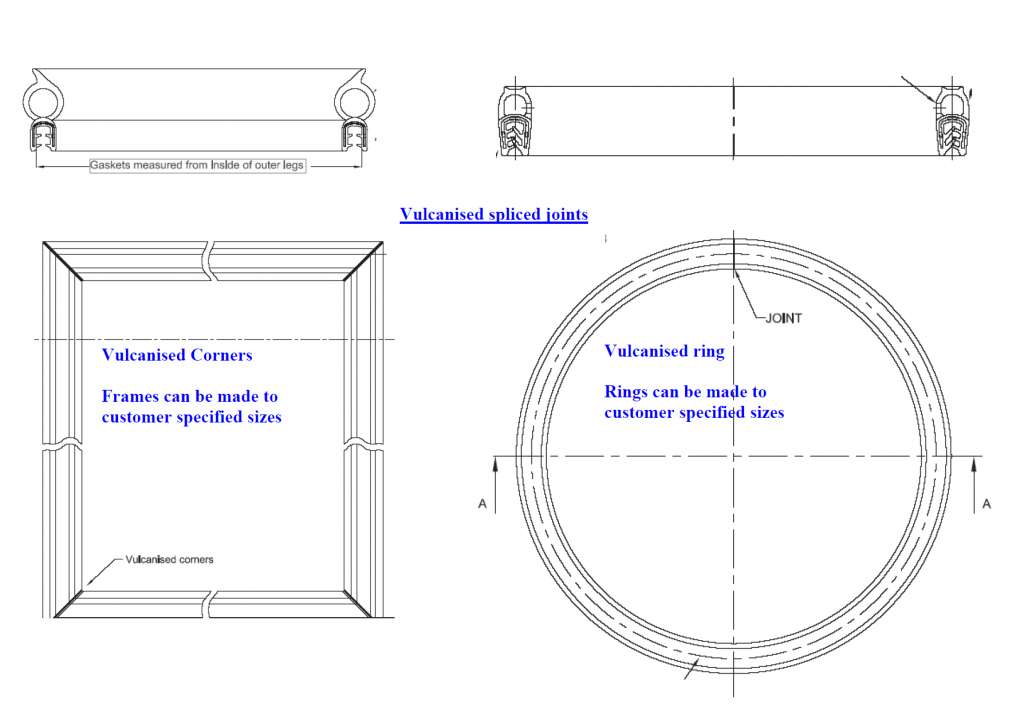

An excellent solution is often the use of spliced joints which can be applied to most profiles using the hot splicing/vulcanising process to chemically bond two ends of a rubber extrusion together, this process effects a reasonably strong and dynamic joint and is particularly effective where there is a requirement for a continuous ring or frame such as windows or automotive applications. Thus, both aesthetics and performance are enhanced while at the same time providing a one-piece installation which is both easier and quicker to install than raw strip which requires corner joints.

Spliced joints ensure that the resilience and dynamic properties of the profile are maintained throughout the joint thus creating an endless seal – so ensuring the gasket is more impenetrable to the elements. This is especially important when a moving vehicle is involved due to continuous flexing of the structure when in service. When compared to glued joints, the vulcanised bond is less messy and easier to install – it is also much longer lasting and does not crystallise, so that it maintains its elastic properties comparably to the rubber section itself.

Download “Structural Aspects of Sealing Profiles” as a pdf document