By Andy Billingham, Managing Director – EMKA (UK) Ltd

Modular cabinet hardware has been with us now for so long it is difficult to imagine what it was like before EMKA developed the ¼ turn Lock, the Swinghandle, rod locks, and all their other modular equipment that makes cabinet building so much easier than it was. No doubt the same will be true in the future when the Electronic Locking Module – today pioneered in the ELM – has become commonplace.

Modular cabinet hardware has been with us now for so long it is difficult to imagine what it was like before EMKA developed the ¼ turn Lock, the Swinghandle, rod locks, and all their other modular equipment that makes cabinet building so much easier than it was. No doubt the same will be true in the future when the Electronic Locking Module – today pioneered in the ELM – has become commonplace.

EMKA’s technological advances are based firmly on a solid platform of high quality mechanical components and constant attention to the needs of their customers, which has generated a steady flow of new technical designs and developments. This development path includes high quality components such as the 1050 programme Hinges, many of which take the form of a low profile with concealed pivot pins, and are particularly suited to outdoor applications.

Variants such as the 1056 feature blind stainless steel pins for increased security and various fixing methods are employed, including countersunk screws, concealed studs, integral rivets. The novel EMKA removable pin fixing is a particularly quick and simple method. Hinges of course come in many sizes and size selection is dependant upon the door – large or multiple hinges may be used if required, e.g. on acoustic canopies, cabinets etc.

Different applications demand different materials and there is a choice within many EMKA product programmes. This includes:

Zinc diecast – suitable for use in external applications and available in powder paint or chrome finish.

Mild steel – plain for weld-on production and plated for bolt-on applications.

Polyamide – a low cost, low weight material, good in mildly corrosive conditions.

Stainless steel – needed in offshore or other harsh environments, e.g. chemical washdown areas, or where ultimate strength is required.

Hinged doors also need gasket sealing for sound, vibration and ingress protection as provided by the EMKA 1011 programme of standard profiles which offers some 30 different types to suit all sorts of cabinet and housing applications for OEMs and specialist manufacturers. Sealing levels up to IP65 are possible and there are EMC variants with protective shield coatings that further enable manufacturers to achieve levels of EMC compliance in sensitive areas.

The 1011 gasket construction often comprises mixed materials to ensure best performance, e.g. by using the durability of PVC with the flexibility of EPDM or the oil resistance of perbunan. Increasingly many sections are UL listed, e.g. to UL50 which defines them as suitable for outdoor applications while others are to UL94HB which refers to their self-extinguishing characteristics.

The EMKA 6000 programme of Toggle Latches was recently introduced to offer specialist equipment builders a solution to their closure needs on boxes, cases, cabinets, access panels, cladding panels and light assemblies. They are also complemented with a series of equipment Lifting Handles for use on storage cases and as cabinet Pull Handles, with/without spring return. 6000 Toggle Latches feature spring (wire) or rigid closure as well as spring loaded vibration resistant mechanisms and may be secured by key locks, padlocks (in various formats), push button release mechanisms or by a simple 180º wing knob. Adjustable claw link operation is also available to aid fitment or to compensate for uneven or variable closure situations.

Quarter Turn Locks are everywhere since EMKA first introduced theirs nearly 40 years ago, and we now rely on them for effective closure of cabinets and panels, taking for granted the large variety of different inserts and key types available. They provide single or multi-point closure and this led in turn to the now universal Swinghandle – such as EMKA’s 1100 programme which developed over many decades to give extensive coverage of customer requirements. Based initially on “the right sized handle to suit the door”, there are now five aesthetic and functional groupings to suit different cabinet styles.

Quarter Turn Locks are everywhere since EMKA first introduced theirs nearly 40 years ago, and we now rely on them for effective closure of cabinets and panels, taking for granted the large variety of different inserts and key types available. They provide single or multi-point closure and this led in turn to the now universal Swinghandle – such as EMKA’s 1100 programme which developed over many decades to give extensive coverage of customer requirements. Based initially on “the right sized handle to suit the door”, there are now five aesthetic and functional groupings to suit different cabinet styles.

Swinghandles were originally designed by EMKA for improved safety, looks and ergonomics. Recent progress has been with a focus on safety by even further reducing the front protrusion when closed – such that now a 9mm thickness is normal.

The natural progression of this evolution was to integrate an electronic mechanism into the 1100 program and couple it with a CAN-BUS network system using SNMP protocols e.g. ELM programme This latest flowering of EMKA innovation combines electronically operated Swinghandle cabinet locks and environmental monitoring in a secure Bus environment especially designed for applications such as process control or telecoms/internet hosting.

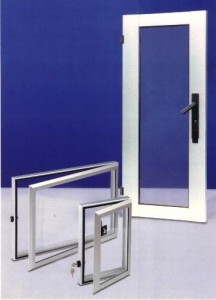

Development of cabinet hardware beyond basic components has been demanded by customer need, leading to the evolution of Aluminium Doors and instrument panels as an essential feature of many applications, e.g. in electronics on controls desks or for display panels. In these situations EMKA offer aesthetic aluminium frame technology, engineered to suit specialist cabinets in standard or custom sizes. They are designed as tamper resistant see-through doors or covers for instrumentation or other information displays such as announcement or mimic panels where they offer cost saving benefits. They are available as complete factory assembled units ready for use on cabinets or as visual panels such as signs for directions, information or advertising.

Development of cabinet hardware beyond basic components has been demanded by customer need, leading to the evolution of Aluminium Doors and instrument panels as an essential feature of many applications, e.g. in electronics on controls desks or for display panels. In these situations EMKA offer aesthetic aluminium frame technology, engineered to suit specialist cabinets in standard or custom sizes. They are designed as tamper resistant see-through doors or covers for instrumentation or other information displays such as announcement or mimic panels where they offer cost saving benefits. They are available as complete factory assembled units ready for use on cabinets or as visual panels such as signs for directions, information or advertising.