Costs of production, assembly, finishing and installation of modern equipment are largely time-dependent because of the high cost of labour involved relative to component costs. Whereas component costs are continuously subject to stringent cost down programs, it seems that overhead and labour rates only increase. Consequently, costs for attaching items such as hinges to an enclosure door and frame can often outweigh the cost of the hinge itself.

Our engineering design team, fully aware of this imbalance have used clever design to counter the trend with our 1110 program hinges. This slick design cuts assembly time close to zero with significant cost savings per cabinet.

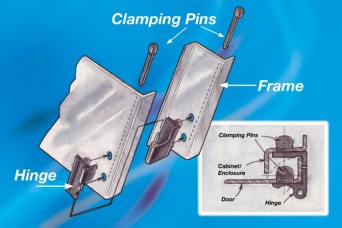

The fabrication process of the cabinet itself is also much reduced, needing only two ten millimetre holes punched in the door and in the enclosure prior to painting. Once paint is dry, hinge lugs placed though the holes accept a glass-reinforced nylon pin that clamps the hinge in place. Careful geometric design ensures that the pins/lugs are self-aligning and compensate for various metal gauges while their self-tightening action provides a solid positive fixing.

Hinge parts of the 1110 program, usually arranged to provide lift-off capability, do not compromise security because the anti-vandal lugs prevent lift-off until the door is opened approximately 70%. Other design features include positioning of the hinge pivot such that a door can be opened 180°, even when the enclosure is placed immediately adjacent to a similar enclosure in a suite style configuration.