So ubiquitous are hinges in our everyday life as access solutions that if “the hinge” did not exist it would be a really urgent matter to invent it – and EMKA would be right up there at the front of the development program! Our ongoing hinge development program covers a welter of approaches to providing that simple axis point in engineering space where door and cabinet, panel and machine can come together, with a degree of freedom that enables the mechanism to operate.

Once invented, the hinge of itself was not the problem – the problem then was and still is – how to provide ways of fitting the hinge while enabling all the other constraints to be met. This is where EMKA’s development engineers have provided very practical solutions. As our MD Andy Billingham explains: “Hinge requirements vary tremendously – consequently we offer everything we can from weld-on flap hinges to cast butt types, screw-on, clip-on, pop-in, plastic, steel, cast and stainless variants.”

Good examples would be for overhead gantry signs, air conditioning units, generator sets, display windows etc.

Design engineers with experience of electrical/electronic cabinet design will appreciate that these are common but specialist applications – just “any old” hinge from a trade supplier will rarely do the job properly or look right, or both. Consequently a perennial problem for specialist enclosure producers is the correct specification and cost effective fitment of suitable hinges.

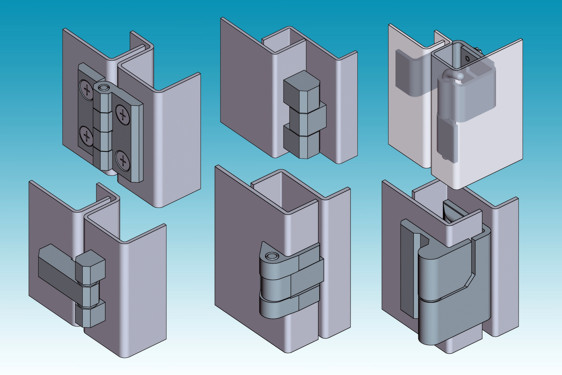

Our EMKA engineers have very much taken this to heart and have developed probably the largest offering of specialist hinges available designed to suit the electrical and electronic industries and addresses the hinging of prominent/lay-on doors with 23 different groupings of hinge types developed in parallel with the growth in electrical and electronic industries. EMKA standardised solutions are special purpose designs to match a defined range of applications, environments and performance criteria, with each type available in various sizes to suit door rigidity, sealing requirements, door loading etc.

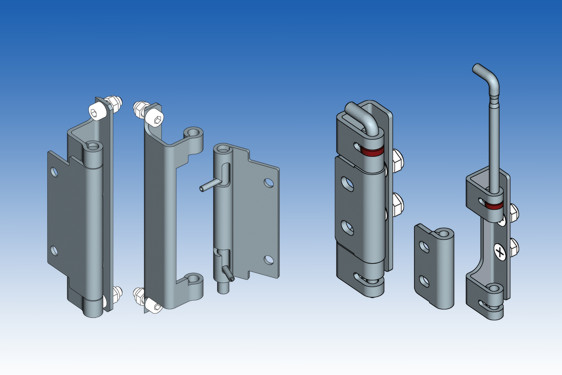

Hinges for prominent doors feature weld-on or fully finished items with traditional screw fixings or fast fixing possibilities. Opening capabilities of 120 degrees to 180 degrees are available as are removable pins or lift-off facilities to speed installation.

In addition we offer a custom hinge capability – a recent example being for a vehicle trailer genset access door requiring an “articulated action” so that the door could be pulled to the side and then swing open with very specific angle and clearance parameters. This was injection moulded in 6 parts with 4 stainless steel pins giving 3 pivot points – the 4th pin enabling rapid demount of the door.

EMKA’s hinge manufacturing technologies encompass mild steel, die-cast zinc, glass-reinforced thermo-plastic and stainless steel, to suit the environmental and aesthetic requirements of the situation. Hinge selection for cabinets with prominent doors really is not now a difficult matter, especially since EMKA’s website includes a simple drill-down architecture for guidance.