EMC versions of our 1016 program attenuate the transmission of electro-magnetic interference across the sealed junction by use of a conductive external skin. Expected applications for 1016 gasket range from gap sealing to noise reduction, e.g. from internal equipment; also vibration damping and impact cushioning on cabinets, furniture and machinery.

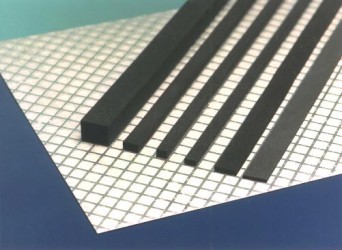

For fire resistance the 1016 program self-adhesive gasket is available to UL94 VO and 94HB ratings, these are also offered in EMC formats to address electrical and magnetic interference. The expanded closed-cell neoprene comes in stock strips from 3mm to 80mm thick and in standard widths from 10mm up to 80mm, with complete custom capability, e.g. for sheets and punched shapes.

1016 series gaskets are produced in neoprene and EPDM, they are self-adhesive for use on clean non-porous surfaces, such as painted/unpainted metal, plastics or on sealed natural materials – varnished timber etc.

Neoprene utilised in the 1016 program tolerates working temperatures of +70°C to -30°C – with fire resistant versions capable within +85°C to -40°C, they offer substantial resistance to many typical commercial/industrial chemicals and gases.