Our engineering team at EMKA pride themselves on their flexibility when catering for individual custom specifications – made possible by our uniquely high level of in-house production whereby we are in control of the entire production flow from the concept to the finished product.

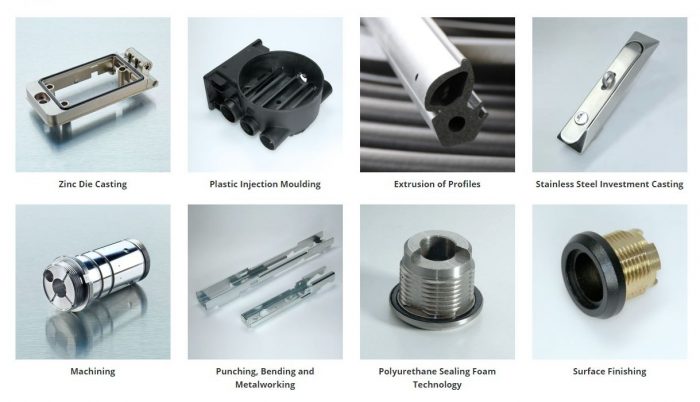

It is important to us that our large standard component production also supports a major capability to meet customer hardware needs beyond the standard. This is possible because of the expertise gained in the casting of stainless steel, injection-moulding of zinc and high-performance plastics as well as in extruding of rubber and plastic profiles. Additional manufacturing technologies are punching, bending, lathe machining, milling and coating of modular product solutions.

During the entire manufacturing process, a high level of product quality and reliability is guaranteed by having our own tool and mould-making department as well as state-of-the-art design, development and testing processes.

Contact us to discuss your non-standard hardware requirements.