While many installations of sealing gasket profiles fit the pattern of a common design, e.g. enclosure door seals, we can readily see from a quick glance at typical applications that often new sections are needed to fit new equipment designs. While being generally of a common concept, e.g. a “P” profile form, the detail design and execution required to perform correctly in-situ may be significantly different from a standard production item. Custom-made products include: frames, rings, lengths, butyl, mastic, flock coating, notching, gluing, slip coating etc.

Custom gaskets therefore fall into three categories:

- Standard sections with second operations, e.g. ventilation holes to release internal pressure from the tubular section or assembled and vulcanised frames where spliced joints ensure that the resilience and dynamic properties of the profile are maintained throughout the joint, thus creating an endless seal.

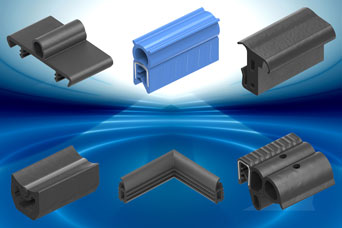

- Integral adaptations, e.g. by adhering a section to a spine so creating a “new” profile from two existing components.

- A complete new design with new tooling incorporating new choices of materials and design criteria.

Gasket manufacturers typically produce a “standard range” of commonly used sizes and styles which they carry in stock as extruded material – and in addition will accumulate over time a stock of tooling which covers all the other sections they have ever made – and from which it is possible to make new gasket. The number of available sections in this way can easily number many hundreds, but even so new sizes and designs are frequently needed to suit specialist applications eg. sealing sunroofs, doors, classic vehicles, buses, Teleco cabinets, or with particular features: dual hardness profiles, wire inserts, ventilated profiles, flame retardant, Nitrile (resistant to oil).

Some common materials used in rubber extrusion include EPDM, SBR, (CR – Neoprene), Silicone, (NBR – Nitrile), and (NR – Natural rubber). Read our whitepaper here for further info…..

Common concerns re materials for custom sections include:

– Comparative features of common rubber/synthetic rubber materials

– Comparative vulcanising properties of NR and other SR’s

– Fluid immersion national and international test methods

– Brittleness temperature of some Engineering Elastomers

– Compression set

– Determination of hardness

– Heat resistance and aging

– Tensile properties

– Specific gravity and density

So customers who think they may require a custom profile gasket are encouraged to contact a specialist manufacturer such as the team at EMKA who can assist with the detail specification and hand hold the process.